- +86-371-65621391

- sale@alumhm.com

- Zhengzhou, Henan, China

La alta niebla salina y la alta humedad del entorno marino imponen exigencias estrictas a los materiales en cuanto a resistencia a la corrosión, resistencia a la fatiga y ligereza. El aluminio 6082, gracias a su excelente idoneidad para entornos marinos, se ha convertido gradualmente en el material predilecto para estructuras de barcos, componentes de cubierta y conectores.

La niebla salina (incluidos medios corrosivos como el cloruro de sodio) en entornos marinos es un importante enemigo de los materiales, ya que provoca fácilmente la oxidación del metal y la corrosión intergranular, lo que puede minar la resistencia de las estructuras de los barcos. La aleación de aluminio 6082, gracias a su diseño compositivo y propiedades superficiales, proporciona una doble barrera de resistencia a la corrosión, respondiendo perfectamente a los desafíos del océano.

En cuanto a su composición, la aleación de aluminio 6082 contiene un contenido de cobre extremadamente bajo (≤0,15 %), lo que evita el problema de la corrosión por picaduras inducida por el cobre. Esta corrosión forma pequeños agujeros en la superficie metálica que penetran gradualmente en el interior, dañando gravemente estructuras críticas del barco, como los soportes de los mamparos y los conectores laterales.

Además, la proporción de magnesio (0,6 %-1,2 %) y silicio (0,7 %-1,3 %) forma una fase de refuerzo estable de Mg₂Si, que no solo mejora la resistencia, sino que también inhibe la propagación de la corrosión intergranular, reduciendo así el riesgo de fragilización por oxidación en los límites de grano.

En condiciones naturales, la aleación de aluminio 6082 forma rápidamente una densa película de óxido (Al₂O₃) en su superficie, aislando eficazmente el sustrato metálico de la niebla salina y el agua de mar. El anodizado puede mejorar aún más esta protección. Incluso tras una inmersión prolongada en agua de mar, la tasa de corrosión de la aleación de aluminio 6082 es de tan solo 0,01-0,03 mm/año, lo que garantiza la estabilidad a largo plazo de las estructuras de los buques.

Durante la navegación, los buques están constantemente sometidos a los efectos dinámicos del impacto de las olas, la vibración y las cargas de carga. Esto requiere que los materiales posean no solo suficiente resistencia estática, sino también una excelente resistencia a la fatiga para evitar el agrietamiento causado por ciclos de tensión prolongados. La aleación de aluminio 6082-t6 presenta un equilibrio perfecto entre resistencia mecánica y resistencia a la fatiga, ideal para aplicaciones marinas.

En cuanto a sus propiedades mecánicas estáticas, la aleación de aluminio 6082-t6 presenta una resistencia a la tracción de 310-350 MPa y un límite elástico de 270-310 MPa, suficiente para soportar estructuras portantes como cubiertas y costillas de buques.

Más importante aún, su resistencia a la fatiga es evidente: bajo las tensiones alternas comunes en entornos marinos (como las tensiones cíclicas inducidas por las olas de ±50 MPa), la aleación de aluminio 6082 alcanza una vida útil por fatiga de más de 10⁷ ciclos, superando significativamente la vida útil por fatiga del acero de la misma resistencia (aproximadamente 5×10⁶ ciclos). Esto previene eficazmente los incidentes de seguridad causados por fracturas por fatiga durante las operaciones a largo plazo de los buques (como el agrietamiento de la cubierta y el fallo de los componentes de soporte).

La aleación de aluminio 6082 también presenta una excelente tenacidad, manteniendo una elongación del 8% al 12%. En caso de impactos repentinos (como colisiones con la costa o impactos de olas fuertes), absorbe la energía mediante una ligera deformación en lugar de una fractura frágil, lo que proporciona protección adicional para la seguridad del buque.

El peso muerto de un buque afecta directamente el consumo de combustible y la velocidad: por cada 10% de reducción en el peso muerto, el consumo de combustible puede reducirse entre un 5% y un 8%, a la vez que aumenta la capacidad de carga y la autonomía. La aleación de aluminio 6082 tiene una densidad de aproximadamente 2,71 g/cm³, solo un tercio de la del acero al carbono marino (densidad de 7,85 g/cm³), lo que la convierte en un material ideal para aligerar el peso de los buques.

Para buques de carga pequeños y medianos, por ejemplo, la sustitución de las cubiertas y los revestimientos laterales de acero tradicionales por láminas de aluminio 6082 (con un espesor ajustado a los requisitos de resistencia, normalmente de 6 a 12 mm) puede reducir el peso total del buque entre un 20% y un 30%. Además, el aligeramiento mejora la maniobrabilidad del buque, reduce la carga del motor y prolonga la vida útil del sistema de propulsión.

Las ventajas del aligeramiento de la aleación de aluminio 6082 son aún más evidentes en embarcaciones de alta velocidad (como buques de pasajeros y yates). Estas embarcaciones requieren altas velocidades, y la reducción de su peso muerto puede aumentar su velocidad de 3 a 5 nudos (aproximadamente 5,5-9,2 km/h) manteniendo la misma potencia. Por otro lado, manteniendo la misma velocidad, esto puede acortar significativamente el tiempo de navegación y mejorar la eficiencia operativa.

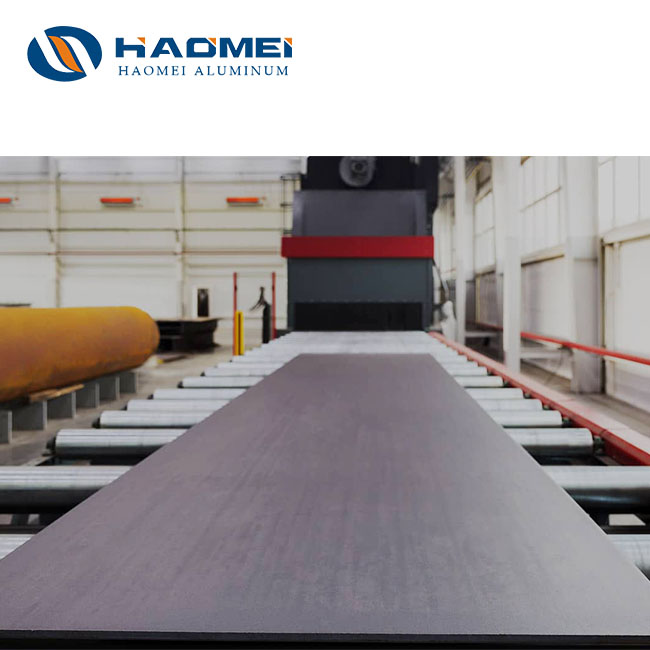

Las estructuras de construcción naval son complejas e implican numerosos pasos de procesamiento, como el doblado de placas, la soldadura de perfiles y el conformado de superficies. El rendimiento de procesamiento del material influye directamente en la eficiencia de fabricación y la precisión del ensamblaje. La idoneidad de procesamiento de la aleación de aluminio 6082 se adapta perfectamente a las exigencias de la construcción naval. El 6082 ofrece una soldabilidad estable y excelentes propiedades de conformado y trabajo en frío.